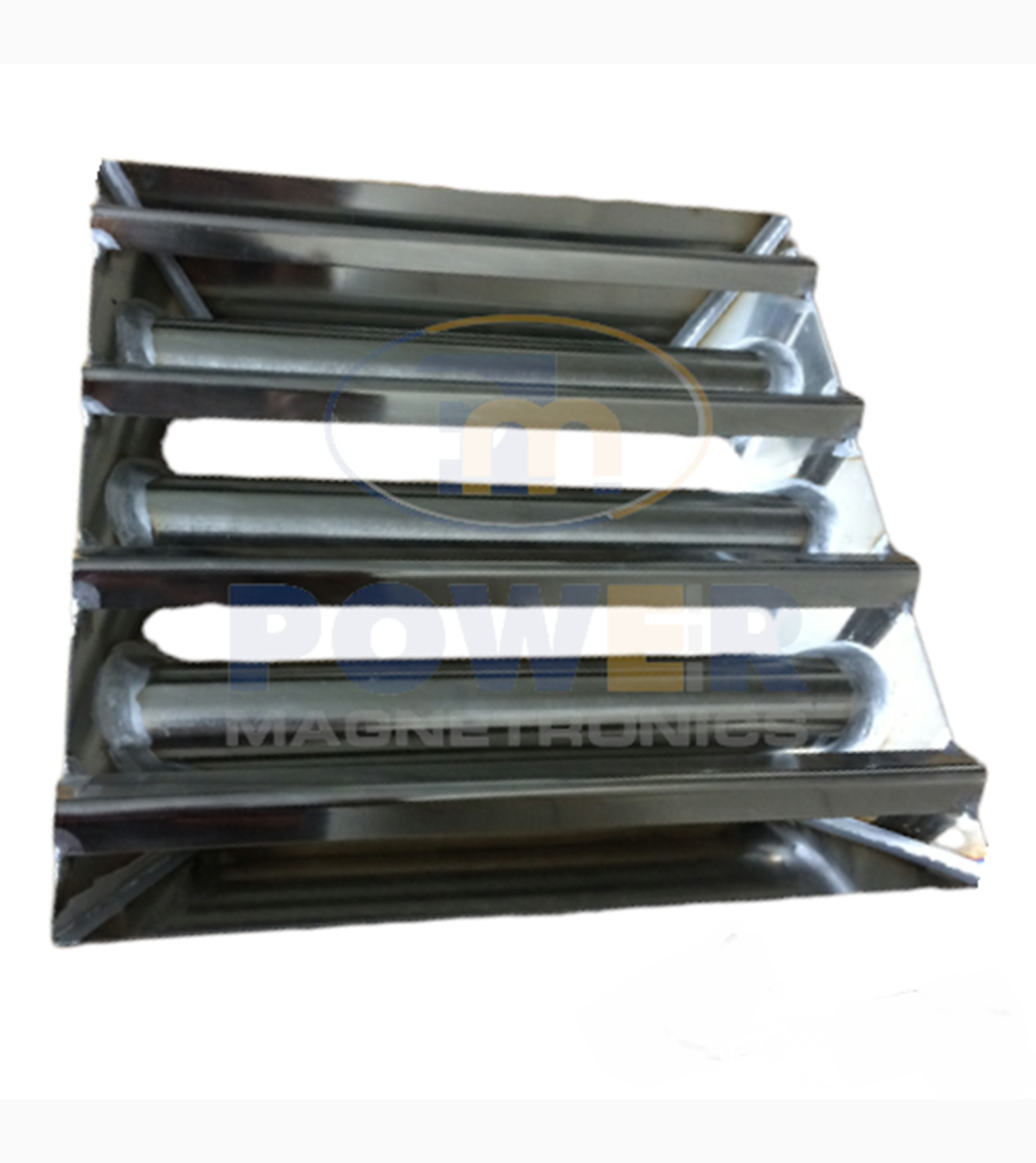

Magnetic Hopper

Product Description

Power Magnetronics make Magnetic Hopper or Hopper Magnet protects processing machinery against ferrous impurities. Magnetic rods fixed onto a stainless steel frameworks, when anything containing iron substances passes through the framework, Iron particles are attracted to the bar magnets by magnetic fields. As a result, your equipments and facilities will be safe and sound, and your products will be safe for consumption. All magnetic rods are manufactured with the use of powerful magnets, which can extract even fine ferrous particles in the form of dust. Power Magnetronics make hopper magnets constructed in three variants namely:

- Low power hopper magnet (2,500 Gauss)

- Medium power hopper magnet (6,000 Gauss)

- High power hopper magnet (10,000-11,000 Gauss)

We at Power Magnetronics do extreme effort in manufacturing the most robust hopper magnet. The surface of frame and magnetic bar can be fine polished and fully welded to meet food grade or pharmacy application. Our hopper magnet is extremely efficient at removing ferrous contaminants from the flow of dry goods such as sugar, grain, tea, plastic pellets, and chemicals powders, which placed in pipeline systems, hoppers, chutes, etc., to separate ferrous particles from materials flowing past the grid, and provide effective protection against contaminants such as dust particles and stainless steel resulting from mechanical wear of processing machinery. It protects different types of machines and other processing equipment from damage, but effectively securing it through passing foreign ferrous particles entering it.

We have achieved great success in developing hopper magnets or grate magnets in accordance with the industry and application area. ​We manufacture hopper magnets in different shapes like round, square, and rectangle as per our customer’s requirement. We can design these magnets to fit in any positions that our customers want to place it.

Features

- Easy installation

- Highly effective and constant performance

- Easy for manual cleaning

- Can be designed to any size and shape

- Double and triple stage grids available

- Powerful magnets assembled

Application

- Flour Mill

- Minerals Industries

- Cattle Feed

- Blow Moulding

- Rice Mill

- Plastic Industries

- Pigment Industries

- Chemical Industries

- Sugar Industries

- Pharmaceutical Industries