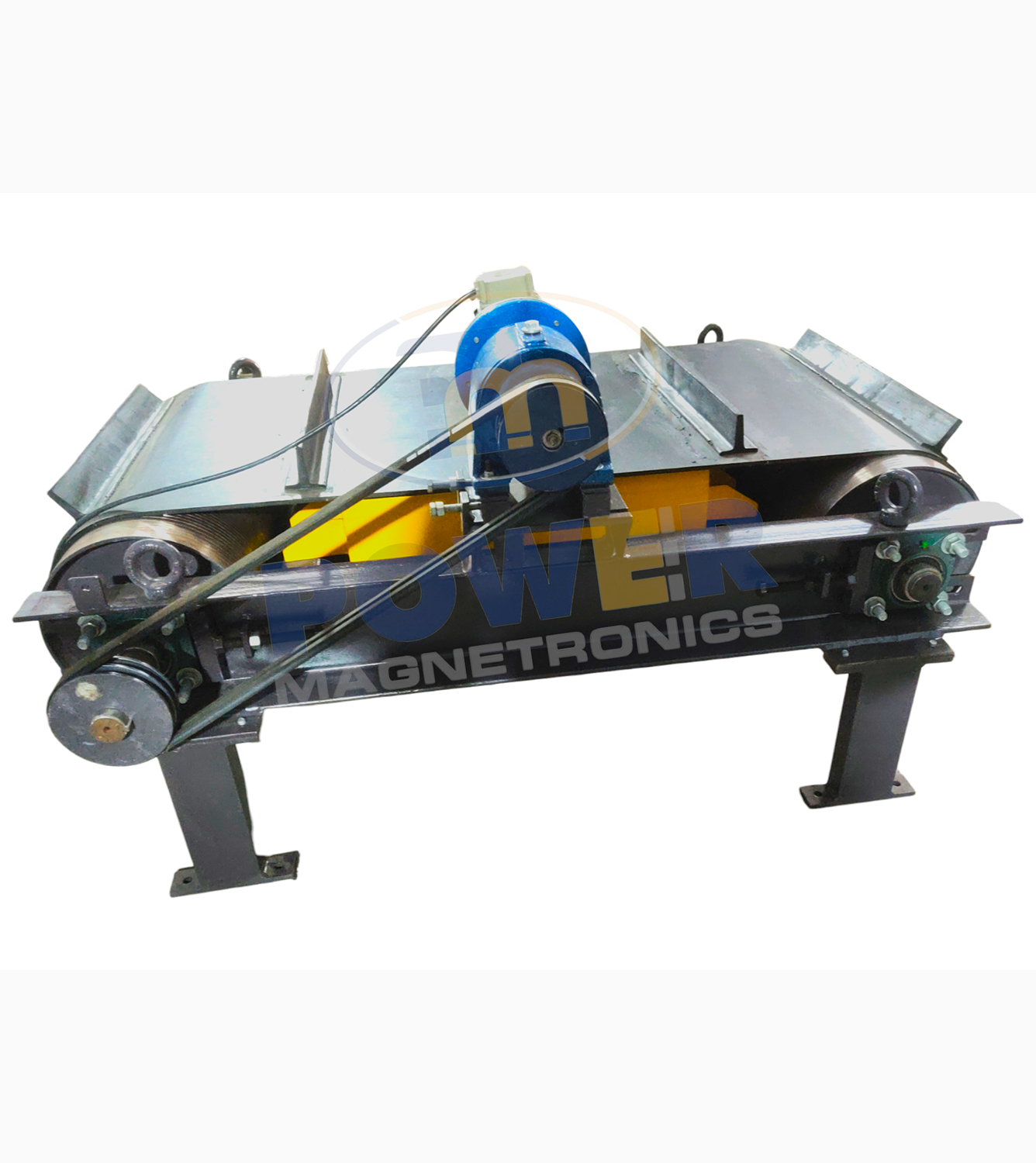

Overband Magnetic Separator

Product Description

Power Magnetronics make overband magnetic separator is designed to capture quickly and easily valuable ferromagnetic particles from a product stream. It is mainly used for the removal of iron particles from materials on a conveyor belt. For this purpose, the magnet system removes all the iron particles from the material flow passing through it. After leaving the magnetic area, these iron particles removed from the conveyor by a heavy-duty rubber belt into a collection drawer at the side of the conveyor. It can Safely and automatically remove tramp iron from heavy product flows. The operational side of the magnet is protected by a wear-resistant S.S. plate. Overbelt magnets are self-cleaning so that no manual cleaning is required. This type of magnetic separator is used to protect, clean and separate materials on applications in the recycling and crushing industries.

Overband magnetic separator can be installed either inline over a conveyor head pulley or across a conveyor belt; if the magnetic separator is installed parallel to the conveyor belt, it is possible to use weaker magnets (as at the end of the conveyor belt the material is quite loose). On the contrary, if the magnetic separator is installed across the belt, we recommend stronger magnets to be used.

For applications that require a magnet to operate above a conveyor, the permanent overband separator is a cost-effective solution for a wide range of industries. Overband magnetic separator is designed to be a lightweight separator with low running costs. The magnet is also self-cleaning, reducing downtime to a minimum. All models are designed to be virtually maintenance-free. We have designed our range of overband magnetic separators for use in multiple applications.

Overband magnetic separators are used for resource recovery, reclaiming steel for resale and separating ferrous contaminants from the other recycle material such as crushed aluminum, glass, plastic, tires concrete, or wood. Many facilities use O.B.M.S. to protect machineries, such as crusher at quarries, cement plants, and mines. At Power Plants, they keep tramp metal out of Coal Pulverizes, Pulp and paper mills use them on wood chips. In Foundries, they remove chills, spruces, and gaggers from sand. We can supply Overband magnetic separator to operate over 300mm – 2000mm conveyor belts. For large conveyor belt widths, overband magnetic separator can be designed with respect to the application.

Features

- Versatile mounting options.

- Low operating costs.

- Self Cleaning, reducing downtime to a minimum.

- Maintenance-free Designed.

- Safety features help to protect both worker and the equipment.

- Customized design available to suit almost any application.

Application

- Reclaiming steel for rescaling and separating ferrous contaminants from recyclable materials such as aluminum, glass, plastic, tires, crushed concrete or wood.

- Recovery of steel from steelworks slag.

- Purification of product by removing iron from material in process such as foundry sand, glass cullet, grain, food products, chemicals, etc

- The extraction of tramp iron from coal conveyors to protect pulverizing mills in power station and screen in collieries.

- Reclamation of either the ferrous or non-ferrous material from open hearth and blast furnace slag, incinerator and garbage plant products, etc.

- Salvage of valuable tools, Cutter bits and machinery parts.

- Pulp & paper mills use them on wood chips.

- Foundries they use to remove chills, spruces and gaggers from foundry return sand.

- Recovery of ferrous metal from household or industrial refuse (Garbage Plant).

- Protection for Processing Equipment such as Crushers, pulverizer, Conveyors, Belts, Screen etc