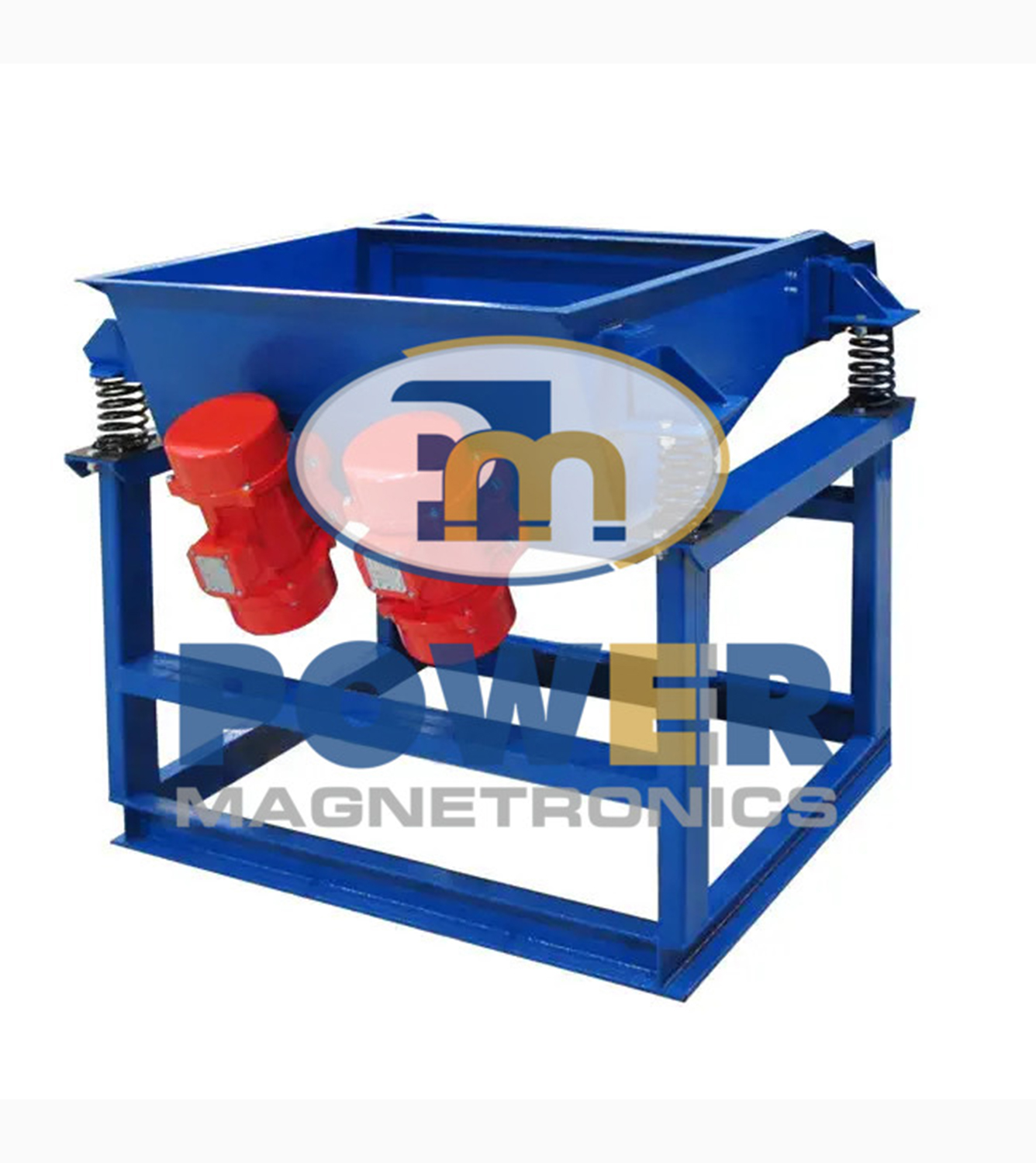

Vibratory Feeder

Product Description

Vibrating Feeder is a kind of linear-direction feeding equipment. It is used to transfer the large size materials and granular materials from hopper to receiving device uniformly, periodically and continuously in the production line, such as to feed materials into the crusher continuously and uniformly also to screen the materials in the sandstone production line.

A vibratory feeder is a device that uses vibration to "feed" material to a process or machine. Vibratory feeders use both vibration and gravity to move material. Gravity is used to determine the direction, and then vibration is used to move the material. The material is almost always a dry material that unlike a liquid, may not move down an incline without some assistance from the vibration effect. The vibratory feeder comes in many shapes and sizes but all use the same principle, which is to feed bulk material at the top in an uncontrolled form and take material out at the bottom at a controlled and steady rate. The vibration source is a vibration motor. Compared with structure of motor, user can reduce the high maintenance cost of shaft and bearings. The vibration motor also has less wearing parts and user-friendly applications.

Types

- Motorized Vibrating Feeder

- Electromagnetic Vibrating Feeder

Features

- Simple operation.

- Rugged, heavy-duty construction.

- Highly reliable.

- Unique tray designs available.

- Quiet operation.

- Easy access to rotary motors.

- Available for hazardous environment applications.

Applications

- Flow-extraction from silo/hopper.

- Flow-regulation for weighing types of equipment etc.

- Flow-feeding for/in processing lines.

- It is been widely used in the food, mining, cement, refractory, iron ore, coal feeding, feed, chemical, and the pharmaceutical industries, etc.